Spiral Freezing Services and Freezer Maintenance

Not all spiral freezers are made the same in fact all spiral freezer are customized to fit your production needs, space constraints, and refrigeration demands.

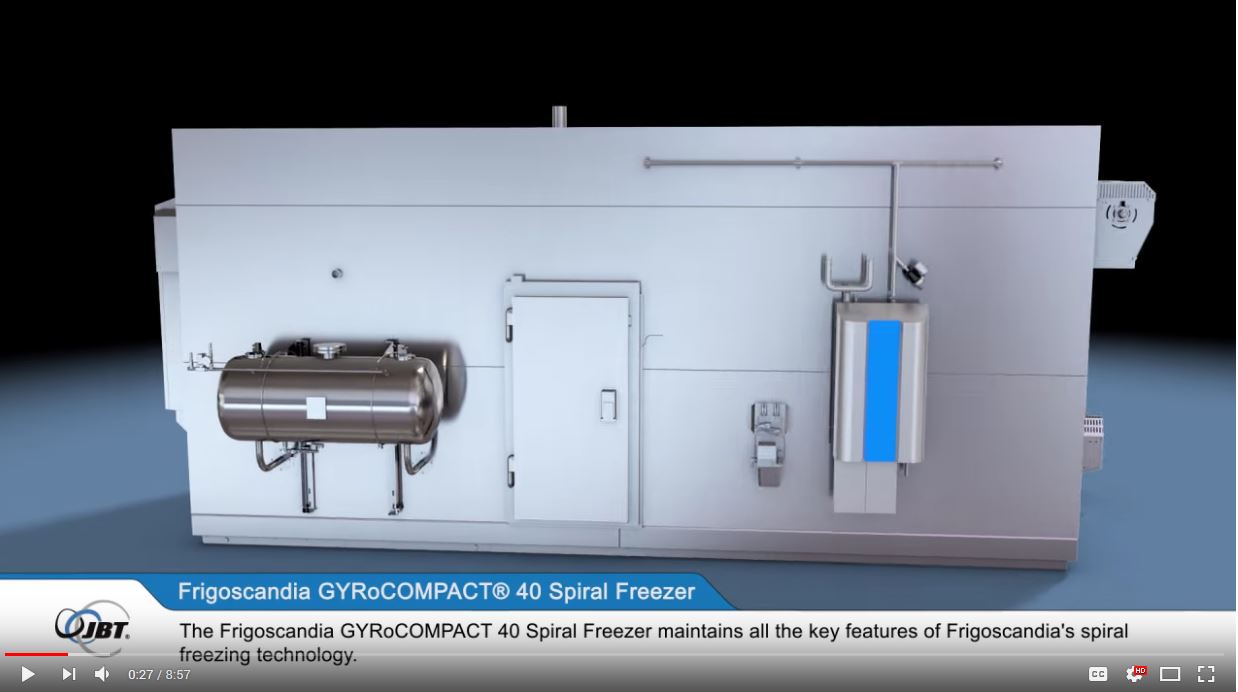

Successful production of high quality frozen and chilled foods relies on the selection of the correct freezing technique and the use of reliable well-designed freezing equipment. Spiral Freezers are a highly space effective method of chilling or freezing a wide variety of food products—in line. Fresh or processed products are directly received from a processing line and returned to the line as frozen or chilled products. No production interruption or unnecessary operator handling.

Freezing systems offer a range of multi-purpose units for the freezing or chilling of naked, in-tray and wrapped products rapidly and safely, like for example beef burgers, fish fingers, chicken parts, gateaux, and ready-made meals.

How do they work? The product is carried through the spiral freezer on a single continuous stainless steel belt, which ascends or descends in a spiral path around a rotating drum. Engineered for high output and low space requirements, the system is housed in an insulated enclosure, utilizing a continuous horizontal air flow over and around the moving belt, across all tires. Horizontal airflow gives the most efficient method of heat transfer in a spiral system. The cooling action is therefore immediate and sustained, efficient yet gentle, thus safeguarding the quality of the products. The entire surface of the belt can also be filled with product without affecting the airflow. The evaporators can be designed with large face areas. This reduces the

The drive is suitable for variable speed operations. This allows the retention time of the product to be varied according to its particular chilling or freezing requirements. In-feed and out-feed transfer points can be arranged to suit site conditions to ensure trouble free transfer of products to and from external conveyors.

All product contact surfaces are manufactured from stainless steel to ensure maximum hygiene. An automatic belt washing, cleaning and drying unit can also be provided to completely clean the belt at the end of each processing cycle.

Spiral freezers are simple to operate and are fully protected. All necessary safety systems fitted are standard. The Spiral freezer is available in a wide range of models designed to meet all capacities and factory layouts. The package model is delivered to site in one piece, connections to services can be quickly made, and the freezer is ready for operation. Larger capacities can be provided for the site, built in unit’s consisting of either one or two drums. Throughputs of up to four tons per hour can be achieved with twin drum models.

- Belt width: it is always better to have more width in order to load more efficiently, or merge two production lines into one spiral

- Belt type: Plastic is the choice for wide belts over 44” because of radius weights, while Stainless is not an insulator as plastic is and actually conducts the cold to the bottom of the product so it a better choice for packaged goods /

- Product clearance: while you may have a 2” thick product today you may have a 4” thick product tomorrow and not be able to run it through your freezer

- Air flow and evaporator design.: Many spiral companies are really material handling manufacturers with no refrigeration engineers employed this is where we win as we have a background of thermodynamics and staffed and experienced engineers to make sure you are getting the most efficient design for your spiral freezing system

- More coil surface: the more area the evaporator has on surface (meaning the area you see not the depth) the more area to absorb frost and allow longer production runs without defrost. While more surface area cost more money to buy it more then pays itself back in the 3 or 4 hours a week you can run for the life of the freezer.

- Patented Sequential defrost: not only do we have the latest issued patent on sequential defrost it is the only process that does not sent the defrost heat into the spiral freezer during defrost thereby not raising temperature in the freezer.