Many food plants rely on freezers and refrigerators to store and ship their products. In last week’s post, I outlined four variables food processors must understand during process freezing. This week, I want to take a look at freezing methods and equipment, and the applications they’re best suited for. Depending on the type and quantity of food, certain freezers are more useful than others.

2 main freezing methods

1. Cryogenic freezing — This method involves spraying or immersing the food directly with liquid nitrogen or carbon dioxide. The product is frozen almost instantly, while the refrigerant is lost to the atmosphere. Cryogenic freezing equipment generally requires lower up-front capital costs than mechanical freezing equipment of the same capacity. However, cryogenic equipment requires significant volumes of refrigerant, which creates high ongoing costs for the producer. Also, cryogenic vapors are colorless and odorless, so care must be taken to ensure adequate ventilation is provided to protect workers from oxygen displacement.

— Cryogenic systems are often used for individual food pieces, like frozen peas. Cryogenic freezing is most often used for individual quick frozen (IQF) products, such as individual chicken wings, frozen peas, or other bulk packaged food items where it is important to maintain individual pieces.

— It is sometimes chosen where space is limited or as a lower-cost means of getting a new product to market quickly.

2. Mechanical freezing — This method involves a standard mechanical refrigeration cycle, using one of the common refrigerants like ammonia or carbon dioxide. Mechanical process freezing systems usually have higher capital costs than cryogenic systems because they require supporting refrigeration systems. But, they’re usually the more efficient and cost-effective option from a long-term standpoint.

— Mechanical freezing is most often used for high-volume production of both raw and finished goods.

Freezer types and their applications

Some freezers are better suited for certain applications than others depending on product type, process conditions or quantity. To ensure the best quality product, it’s important to choose the freezing equipment that creates the most efficient freezing process for your specific product. Below are several types of freezers and their typical applications:

— Process freezer — Process freezers are typically incorporated into the manufacturing line for cooked products, situated between cooking and packaging.

— Individual Quick Freeze freezer — IQF freezers can be mechanical, but are most often cryogenic systems. They’re ideal for protein served in small pieces such as diced ham, wings, meatballs or shrimp. They can also be used for fruits and vegetables and prepared foods like pizza or pasta.

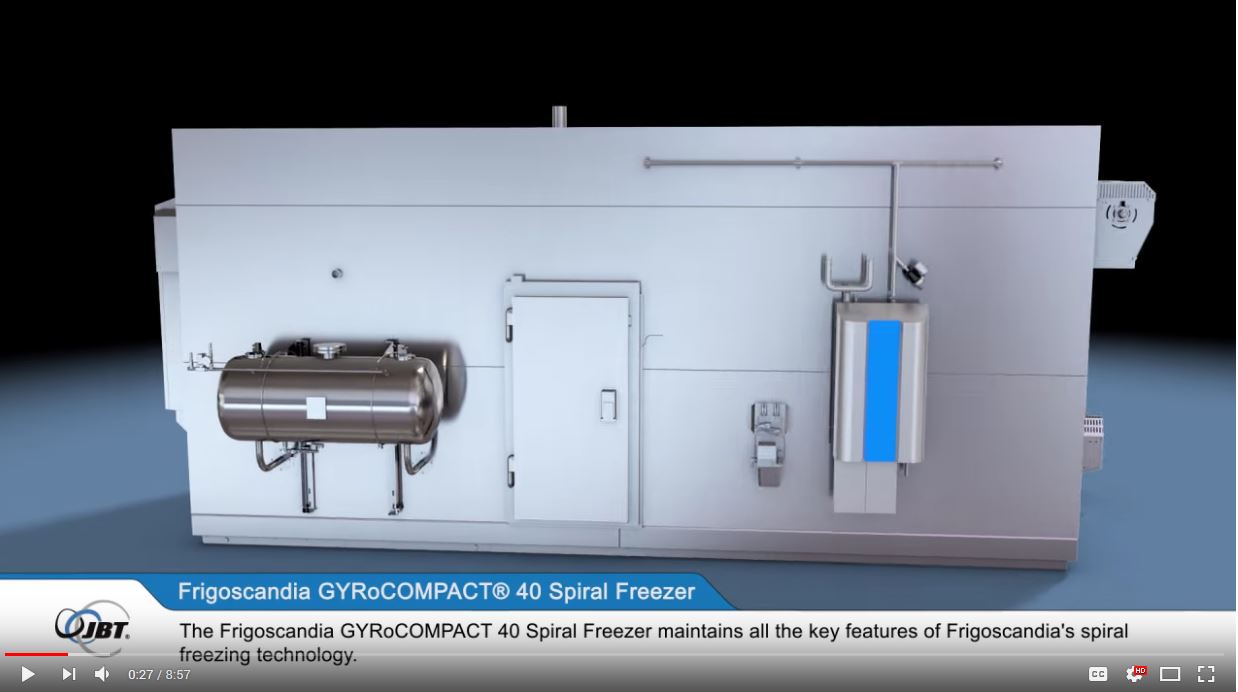

— Spiral freezer — Spiral freezers can be either mechanical or cryogenic, and move the product along a spiral conveyor through a room for about 45 minutes until it is frozen.

— Tunnel freezer — Tunnel freezers work in the same fashion as spiral freezers, but they move the product linearly, rather than in a spiral pattern.

— Plate freezer — A plate freezer is a special hollow plate that has liquid refrigerant flowing through it. Products are placed between two plates and evenly cooled to freezing temperatures. These freezers are ideal for flat products or brick-shaped packaged products, such as frozen meals.

— Blast freezer — Blast freezers are mechanical systems generally used to freeze products in bulk on pallets. Blast cells are not part of the manufacturing line like process freezers. The food is sealed in a blast cell and remains there for multiple days as cold air is continuously circulated throughout the room.

When selecting the proper freezing equipment, it’s helpful to work with a refrigeration equipment provider to determine which system is best suited for the specific product. Often times, food plant owners can work with providers to create a custom-designed system to fit their needs perfectly.

Read article

Contact ICM LTD today specialists in maintenance, repair, installation of spiral freezers for the frozen food industry.